Image

Aug,16,2023 << Return list

For 90 years, the Aluminum Association has been proud to be the

industry's voice — telling the story of the aluminum industry in the

United States and to the world. This long-term success wouldn’t be

possible without the support and leadership of member volunteers across

generations.

1930s — A New Era

Image

In 1933, President Franklin Roosevelt signed the National Industrial Recovery Act, asking industries to establish guidelines for fair competition during the New Deal. “The Association of Manufacturers in the Aluminum Industry” met in Pittsburgh in August of that year and reorganized as “The Aluminum Association” as we know it today in 1935. In 1938, the Aluminum Association met at the Waldorf Astoria in New York City to recognize the 50th anniversary of the aluminum industry.

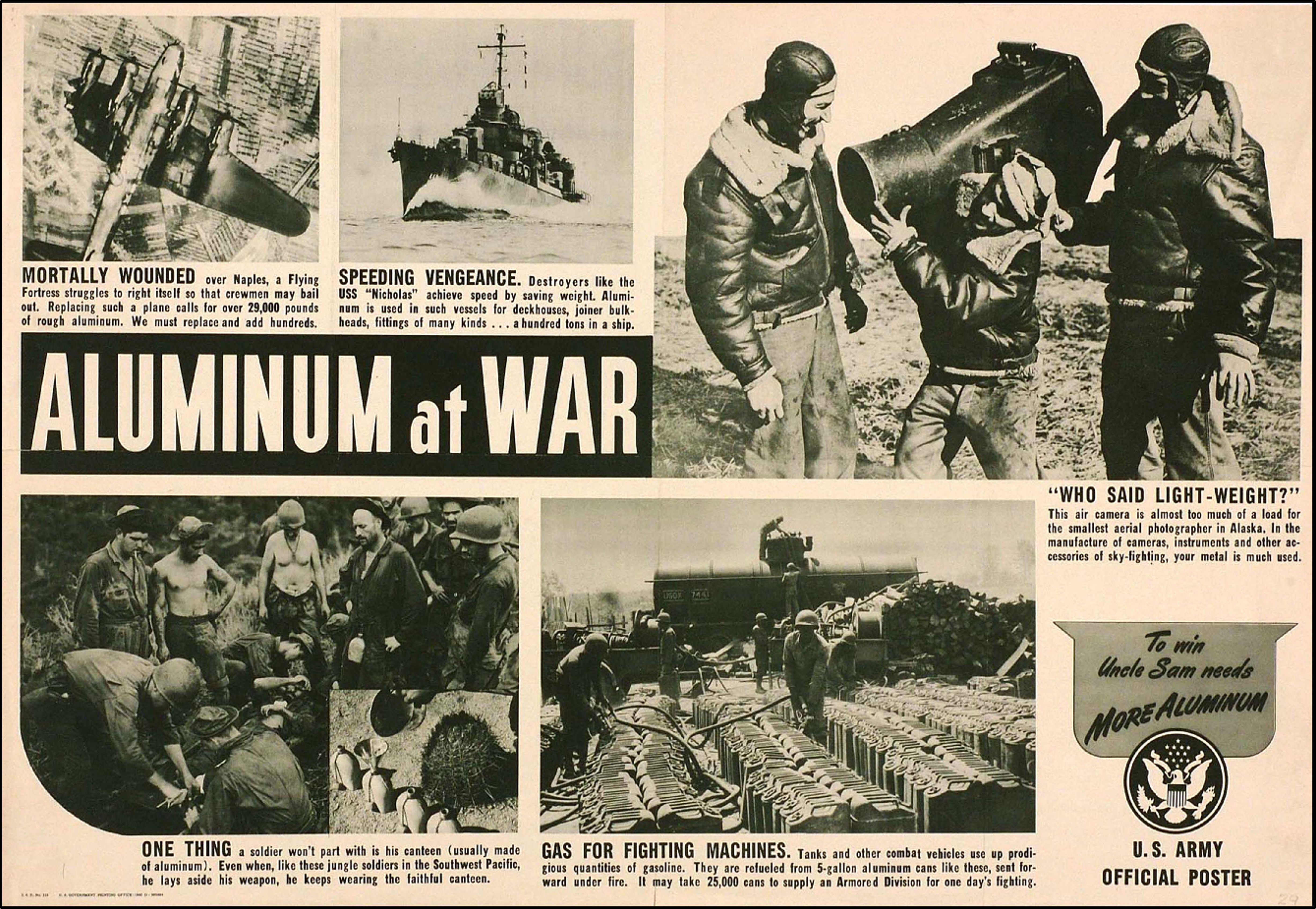

1940s — Aluminum & World War II

As a part of FDR’s “Arsenal of Democracy,” aluminum production expanded nearly 10x in the last years of the 1930s. Energy infrastructure changes brought on by the New Deal, such as the Tennessee Valley Authority, drove the expansion of a significant U.S. smelter base. Aluminum was vital to the war effort, particularly in munitions, shipbuilding and aviation. A single B-29 Superfortress bomber used around 50,000 pounds of Aluminum, two-thirds the weight of the entire aircraft. Throughout the war, the aluminum industry designed and built more than fifty new aluminum production and fabrication plants in coordination with the U.S. government. The Aluminum Association served as a critical coordinating point for the industry during the war – liaising with the government, developing early industry statistics and organizing a recruiting campaign to bring more women workers into aluminum plants.

Image

1950s — Standardizing the Metal

After the war, the aluminum industry pivoted production to meet the demands of a growing consumer economy. Around the country, aluminum was everywhere. It was in packaging, commercial aviation, home appliances, the built environment and more. This called for a standardized system to better facilitate the flow of metal across markets. The association readily responded with an industry Technical Committee in May of 1954, which created the alloy designation system still in practice today. The initial list in 1954 had 75 unique chemical compositions for aluminum alloys. Today, that list includes more than 530 compositions.

Learn more about industry standards

1960s — Tracking the Data

In the 1960s, the economy expanded and the Aluminum Association along with it. The association’s first professional executive director, SL Goldsmith, was appointed. This decade also marked the beginning of the association’s statistical tracking and reporting program with the release of the first Aluminum Statistical Review in 1962. 60 years later, the association's statistical program develops more than two-dozen ongoing industry statistical reports.

Image

1970s — Birth of U.S. Recycling

Image

The aluminum industry had long worked to reintroduce as much material as possible into the system for re-melting and re-use to reduce costs and conserve energy before the 1970s. However, with the rise of the conservation and recycling ethos of the 1970s and with more aluminum in the hands of consumers, modern recycling was born. The industry built the consumer recycling system as we know it today, beginning with mobile collection units, can drives, state recycling refund programs and more. The recycling movement taught consumers about the need to bring aluminum back into the creation system which is one reason that aluminum cans are the most recycled beverage container on earth.

1980s — Aluminum Takes Flight

Aluminum was a crucial component in the space shuttle program. In fact, aluminum was critical to the history of aviation dating back to the Wright Brothers, who used aluminum casting to house the engine for their plane’s 12-second, 120-foot flight at Kitty Hawk. The metal was used extensively in the Apollo space program, and it particularly shined during the shuttle program in early 1981. Aluminum’s low weight, high-strength and thermal properties all make it the ideal material for space exploration to this day. Today, you can see aluminum in action at the Udvar Hazy Air & Space Museum, where the Space Shuttle Discovery is on display.

Image

1990s — Growth of Automotive Aluminum

Image

Aluminum’s growth in the automotive market really took off during the 1990s. Automakers sought to meet the demands for safety, high-performance and fuel-efficiency from consumers and the government, and the Aluminum Association was there to help. The association created the Auto Aluminum Alliance to bring automakers and the industry together to get more aluminum into the vehicle. A Detroit office opened for the Autos and Light Truck Group, a precursor to today’s Aluminum Transportation Group. The 1990s laid the foundation for vital industry work in the automotive market that continues to this day.

2000s — Sustainability at the Forefront

In the 2000s, issues of emissions, sustainability, and climate were at the forefront of the public and industrial consciousness. The Aluminum Association took a future-leaning approach to these issues, working on voluntary programs with the EPA and endorsing cap and trade carbon policy. The association successfully reduced PFC emissions overall by more than half. Our work was recognized by the EPA and the association received the Climate Leadership Award in 2002. In 2008, the association launched a formal, full-time sustainability initiative to engage on policy, develop data and widely communicate industry progress on carbon, recycling, and more.

Image

2010s — Global Trade Era

Image

With the persistent unfair trade practices in China, the 2010s were defined as a decade of renewed focus on global trade. The industry rose to the occasion, coming together with a united position advocating for a commitment to fair trade and strong trade enforcement of frequently broken rules. Section 232 tariffs on aluminum, an admittedly imperfect tool, brought some stability to a market that was facing real challenges. Despite different positions in the supply chain, the industry has managed to stay united on a principled global trade approach.

2020s — The Road Ahead

What comes next is up to us. Much like the United States itself, aluminum faces all sorts of challenges. From geopolitical strife to supply chain issues to climate pressures, the aluminum industry will struggle and thrive in this new environment of the 2020s and beyond. We have no doubt that the industry will persevere and contribute to the well-being of humanity just as it has done over the past 90 years.

Aluminum is more than a metal – it is our shared history, part of the American story. Now, we write the next chapter.

Image

Source:Aluminium Association